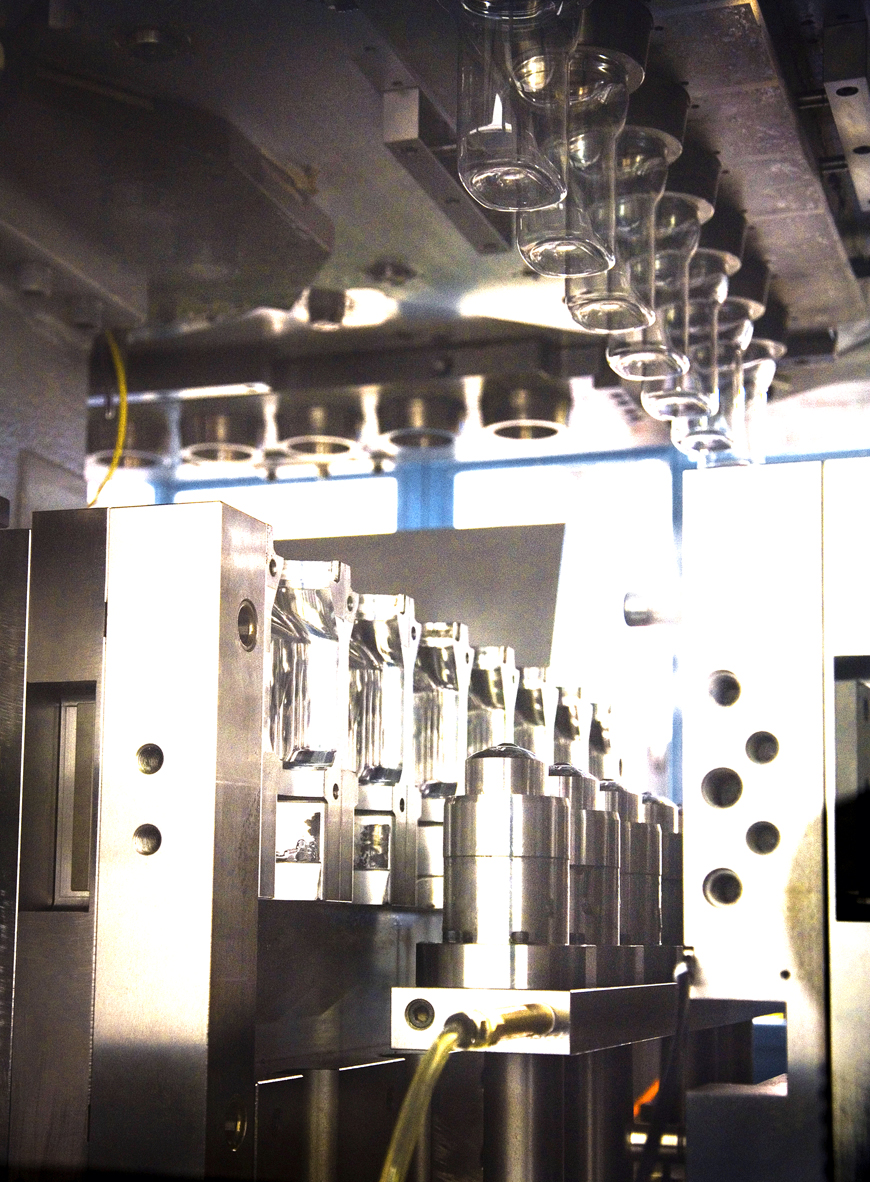

Injection Stretch-Blow Molding Services

Injection Stretch-Blow Molding Overview

Injection Stretch-Blow Molding (ISBM) is a manufacturing process for producing large quantities of bottles and jars by creating a preform using the Injection Molding process. The preform is then stretched and blown into the final desired shape. CMG’s Injection Stretch-Blow Molding machinery gives us the ability to produce a wide variety of bottles and containers for applications such as beverages, household chemicals, foods, spices, pharmaceuticals, personal care products and more.

Injection Stretch-Blow Molding Company Capabilities

CMG, a premier blow molding company, operates one-step ISBM machines in both of our facilities and currently produces a wide variety of bottles with narrow necks up to wide mouth jars. We manufacture bottles (e.g., 24-410 pet bottles) & containers with our efficient single stage machines using the following plastics:

We manufacture parts using the following Stretch-Blow Molding materials:

- Polyethylne Terephthalate (PET)

- Polypropylene (PP)

- Polyethylene (PE)

- Polycarbonate (PC)

- Additional materials are available

Contact us below to receive a quote.

![]()

CMG Plastics USA

Somerville Plant (Headquarters)

160 Meister Avenue, Suite 1

Somerville, New Jersey, 08876

CMG Plastics Canada

Brantford Plant

99 Savannah Oaks Dr, Unit 6

Brantford, Ontario

N3V 1E8, Canada