Collaborative robots, or as they are more accurately called, “cobots,” are robots designed to work alongside humans in a shared work environment.

These technological marvels of efficiency and performance are the latest example of how CMG Plastics is constantly searching for ways to improve operations and increase manufacturing productivity.

If you have been keeping up with our blogs, you are probably familiar with several other recent happenings at CMG Plastics, including tapeless boxes, the blue light visual warning system, and a unique polybag packaging format.

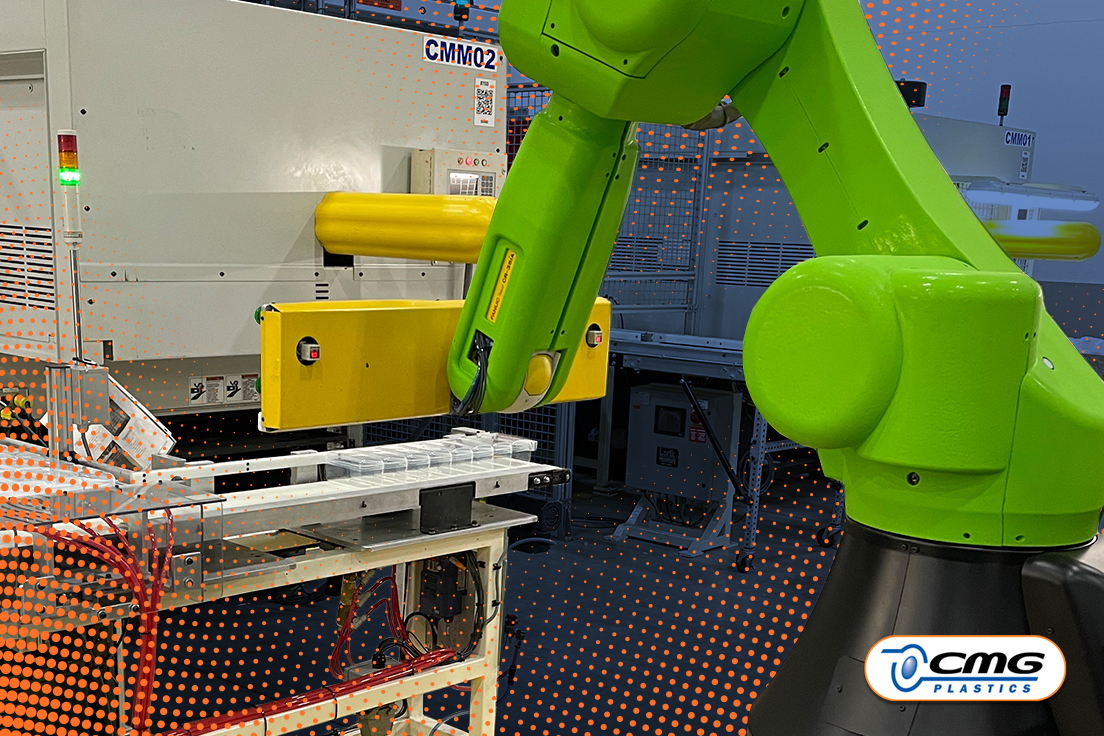

We have just “hired” our first cobot and put it to work at our Branford, Ontario facility. Rather than replace human workers, cobots are “intelligent” mechanized entities specifically designed to assist and collaborate with people. In manufacturing, cobots are gaining in popularity due to their ability to enhance productivity, efficiency, and safety.

Here are several ways cobots are making an impact in manufacturing operations:

PACKAGING AND PALLETIZING

Cobots are often employed for packaging and palletizing operations to handle repetitive tasks, such as picking up products from conveyor belts, placing them in packaging materials, sealing packages, and arranging them on pallets. Highly adaptable, they can easily be reprogrammed to accommodate different product sizes and packaging requirements.

MACHINE TENDING

Cobots can tend to various types of machines, including CNC machines, injection molding machines, and 3D printers. They can load and unload workpieces, start or stop machine operations, and perform routine maintenance tasks. This frees human operators to focus on more complex and cognitive tasks, while the cobots handle the more tedious and repetitive machine operations.

ERGONOMICS AND SAFETY

By undertaking physically demanding and hazardous tasks, cobots reduce the risk of injuries to human workers. They can be equipped with safety features, such as force sensors, collision detection systems, or speed monitoring, to ensure safe interactions with humans.

At the end of the day, metaphorically speaking, cobots offer the potential to enhance manufacturing processes by combining the best attributes of human workers and robotic automation. They can increase productivity, improve product quality, and create safer and more ergonomic work environments in manufacturing facilities.

At CMG Plastics, we are always sourcing the latest packaging and manufacturing technologies and offering advancements that help clients meet and surpass their goals and challenges.

Contact us today and let’s talk about how we can help you exceed yours.

The cobots are waiting.