Injection Stretch-Blow Molding

Home | Injection Stretch-Blow Molding

At CMG PLASTICS, it’s more than your package. It’s our mission.

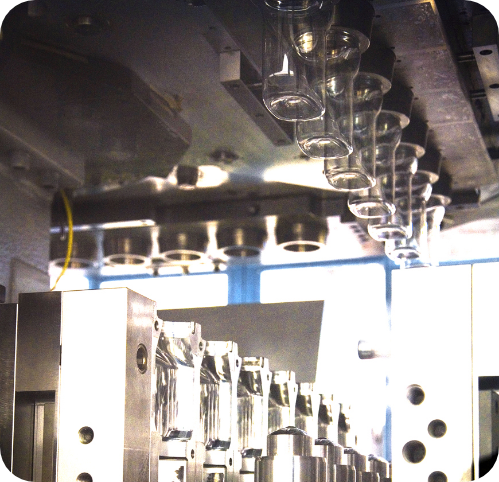

THE PROCESS

Injection Stretch-Blow Molding (ISBM) is a manufacturing process for producing large quantities of bottles and jars by creating a preform using the Injection Molding process. The preform is then stretched and blown into the final desired shape.

CMG Plastics’ Injection Stretch-Blow Molding machinery gives us the ability to produce a wide variety of bottles and containers for applications such as:

- Beverages

- Household Chemicals

- Foods Spices

- Pharmaceuticals

- Personal Care Products

- Many Others

INJECTION STRETCH-BLOW MOLDING CAPABILITIES

As a premier blow molding company, we operate one-step ISBM machines in each of our facilities producing a wide variety of bottles from narrow necks to wide mouth jars.

We manufacture parts using the following Stretch-Blow Molding materials:

- Polyethylene Terephthalate (PET)

- Polypropylene (PP)

- Polyethylene (PE)

- Polycarbonate (PC)

- Additional Materials Are Available