Injection Molding

Home | Injection Molding

Great relationships.

Great quality.

And of course,

great packaging.

THE PROCESS

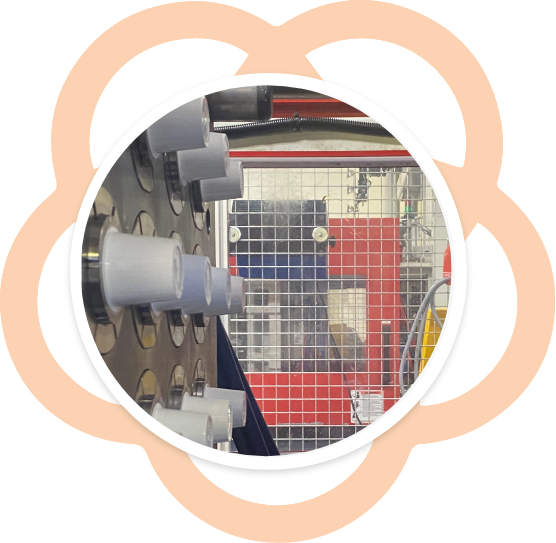

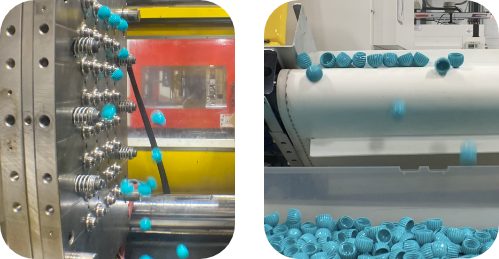

As a cost-effective manufacturing process for producing large quantities of high-quality parts with tight tolerances, Injection Molding (IM) is the ideal solution. It involves injecting molten plastic material into a tool (mold) under high pressure and then quickly cooling it in a highly repeatable process.

INJECTION MOLDING CAPABILITIES

CMG Plastics produces a wide variety of functional, high-quality parts in a virtually infinite array of shapes, wall thicknesses, and textures, using molding machines with clamping forces up to 600 tons that accommodate all cycle time requirements.

From prototyping to production, we manufacture high-quality products using the following thermoplastic materials:

- Polypropylene (PP)

- Polystyrene (PS)

- Polyethylene (PE)

- Polycarbonate (PC)

- Additional Materials Are Available

CMG Plastics’ custom injection molding services also include In-Molding Labeling and Decorating which enhance the value of your final product while helping eliminate costly, time-consuming secondary operations.