In the previous article, we discussed five advantages of in-mold labeling for CPG brands customers and the environment, including:

In the previous article, we discussed five advantages of in-mold labeling for CPG brands customers and the environment, including:

- Shape versatility: Round, oval, square, and rectangular, as well as lids.

- Advanced aesthetics: Various textures, colors, finishes and images.

- Highly Functional: Modern features that enhance brand appearance and function.

- Durability: Superior resistance to wear, scratches, tears, heat, and humidity.

- Sustainability: Fully recyclable and reusable without a separate the label.

Of course, that does not mean you can just dive into the in-mold labeling process without carefully considering how your design will affect the manufacturing process and the final product. Here are key product and mold factors to consider.

The Impact of Shape

In-mold labeling can accommodate many different shapes, but two key features need to be addressed – part taper and gate location. Every degree of taper helps get the label into the cavity and the mandrel out of the cavity without disturbing the label. Less taper could lead to increased scrap or slower cycles. Also, gate location will affect the flow of resin over the label. When resin flow crosses the edge of the label, resin can get behind the label and cause “blow-by” defects, so it is important to choose the optimal gate location to minimize resin flow across the edge.

Lid Considerations

Flat in-mold labeling lids are generally reverse-gated from the core. Material is injected directly opposite the label, which essentially “pins” the label in place so it does not move during the molding process. In applications that involve gating directly on the label, pay close attention to gate size and type to minimize any shear heat because excessive heat may cause label distortion.

Wrap-Around Labels

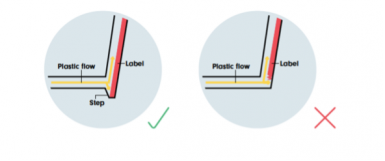

Cups with wrap-around labels are not gated directly onto the label. As a result, other design features may be needed to anchor the label in the cavity. For example, a label step is used in this package to secure the label in place.

Label Edges

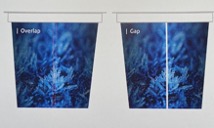

Consider the artwork of your label and how it will line up at the edges where the label comes together. There are two options to ensure a visually appealing package. You can either overlap the edges by 3mm or leave a 3mm gap.

Materials Used for In-Mold Labeling

Polypropylene (PP) is used for in-mold labeling projects, while high-density polyethylene (HDPE) and polystyrene (PS) are options for specific applications. The decision about which label substrate to use is often based on the product environment, such as:

- Hot fill applications +190°F

- Retort process (pasteurization or sterilization)

- Aggressive conditions (chemicals)

- Repeated dishwasher cycles

- Deep freezing

We’re ready to help!

CMG has one of the most experienced teams in the industry. We can provide you with the information you need to make smart decisions that enhance your brand and the customer experience you provide. If you have questions about in-mold labeling mold and product considerations, contact us today. We look forward to helping you and will get back to you promptly.